How is drain relining done?

1. Drain Inspection

The first step of the drain lining process is that we will perform an exhaustive evaluation of the current state of the pipes, and the extent and severity of the damage. CCTV cameras are used to survey the insides of the pipes to make informed decisions on how to fix the defects.

2. Clearing Of Debris

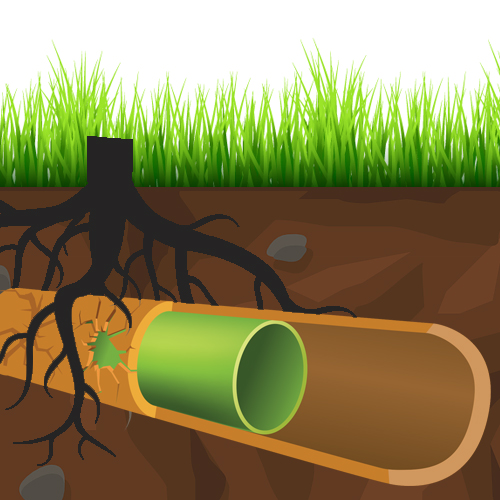

The next step is to clear out any blockages inside the pipes. These may include tree roots, piled-up debris or any other waste matter clinging to the insides of the pipelines. Usually, we use hydro jetting machines to remove these blockages, which is followed by a thorough cleaning session. This step is important and non-negotiable because a clean surface ensures a stronger bonding of the relining material to the pipes.

3. Preparing the lining

Different types of drain damage require different types of pipe lining. On the third step we will prepare and finalize the type and dimensions of the required pipe lining based on the requirement.

4. Installation

There are two ways we install pipe lining in the drains. The first method is called inversion, where a resin mixture is poured into the drain liner and rolled repeatedly. The mixture needs to be distributed consistently to get the desired thickness. The final structure is then inserted into the damaged pipe with the help of inflated airbags and fitted to the shape of the pipe walls using water pressure. The second method is called GFRP UV pipe lining. In this method, the lining is inserted into the defective pipe using standard cables and tools.

Both methods are equally effective. We can ensure you that the installation is done only by trained technicians because accurate fitting is crucial for efficient drainage and durability.

5. Treatment

Once the installation is done, the lining is allowed to harden and bond with the insides of the pipes. If we are using the inversion method of lining, it will harden by itself. If necessary, we will use hot water to accelerate the hardening process. If it is the GFRP UV process, the pipelines need UV lighting exposure to achieve the desired hardness.

6. Follow-up Inspection

Our technicians will conduct one final round of evaluation and inspection on the effectiveness of the curing process and that the pipeline is now ready and good to go. This inspection is also done using CCTV cameras.